<!-- x-tinymce/html -->

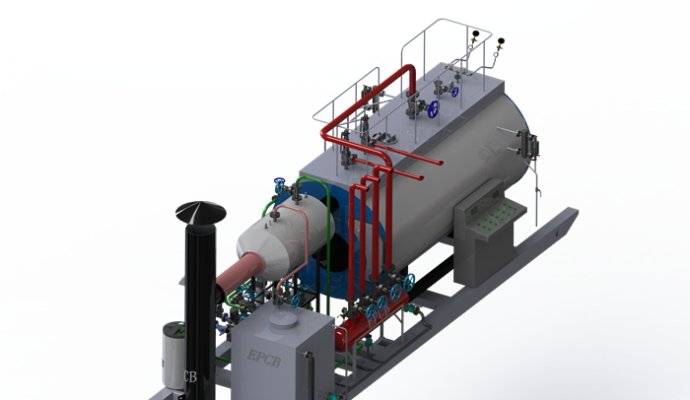

A three pass oil fired steam boiler is a highly efficient industrial boiler that uses oil as its primary fuel source and is designed with a three-pass heat exchange system. This unique design allows hot gases from combustion to pass through the boiler three separate times before being released through the chimney. The multiple passes ensure maximum heat transfer to the water, resulting in higher thermal efficiency, reduced fuel consumption, and consistent steam generation.

Unlike conventional single pass or two pass boilers, the three pass system minimizes heat loss and utilizes combustion energy more effectively. This makes it one of the most reliable and widely preferred choices for industries that require continuous and high-quality steam for production processes.

The importance of the three pass design lies in its ability to optimize energy usage. In a three pass oil fired steam boiler, the combustion gases first pass through the furnace, then travel through tubes in the second pass, and finally move through additional tubes in the third pass before exiting the system. This extended contact between hot gases and water significantly improves heat absorption.

As a result, the boiler achieves higher efficiency levels compared to traditional designs. The improved heat transfer not only saves fuel but also reduces operating costs. Additionally, the design helps in lowering flue gas temperatures, which minimizes heat loss and contributes to environmental sustainability.

The working principle of a three pass oil fired steam boiler is based on efficient fuel combustion and maximum heat transfer. Oil is atomized and mixed with air in the burner, where it ignites and produces high-temperature gases. These gases enter the furnace chamber, where the first pass occurs. Heat from the gases is transferred to the surrounding water, initiating steam generation.

In the second pass, the partially cooled gases flow through a set of tubes surrounded by water. This stage ensures further heat transfer and increases the steam output. Finally, the gases move to the third pass, where they flow through another set of tubes before being discharged through the chimney. By the end of the third pass, most of the heat has been extracted, leaving only low-temperature gases to exit the system.

One of the key advantages of a three pass oil fired steam boiler is its superior efficiency. The extended heat transfer process allows industries to produce more steam while using less fuel. This directly reduces operating costs and improves profitability.

Another advantage is durability. Since heat is evenly distributed across multiple passes, the boiler experiences less thermal stress, extending its lifespan and minimizing maintenance requirements.

The design also ensures low exhaust gas temperatures, which reduces environmental pollution and helps businesses comply with emission regulations. For industries that prioritize sustainability, this makes the three pass oil fired steam boiler a valuable investment.

Three pass oil fired steam boilers are widely used in industries that depend on steady and reliable steam production. In the textile industry, they are essential for processes such as dyeing, drying, and fabric finishing. In the food and beverage industry, they provide the necessary steam for cooking, sterilization, and pasteurization.

Pharmaceutical and chemical industries also rely heavily on these boilers for precise heating and sterilization processes. Paper mills use them for pulping and drying, while hospitals and hotels utilize them for centralized heating and hot water supply. Their adaptability to different industrial needs highlights the versatility and importance of the three pass design.

When compared to single pass or two pass boilers, the three pass design is significantly more efficient. Single pass boilers allow combustion gases to exit quickly, resulting in high flue gas temperatures and wasted heat. Two pass boilers improve on this by extending the gas travel path, but they still fall short of the efficiency provided by three passes.

The three pass oil fired steam boiler maximizes combustion energy utilization, achieving higher steam output with lower fuel consumption. This not only reduces costs but also minimizes the carbon footprint, making it a more environmentally responsible option for industrial operations.

Before investing in a three pass oil fired steam boiler, businesses should evaluate their steam capacity requirements, available installation space, and long-term fuel costs. It is important to ensure that the chosen model matches the industrial load demand, as both undersized and oversized boilers can lead to inefficiencies.

Another critical factor is compliance with emission standards. Modern three pass boilers are designed with advanced burners that ensure complete combustion, reducing pollutants. Companies should also consider after-sales support, spare parts availability, and the reputation of the manufacturer to guarantee reliable performance over time.

Sustainability has become a major concern for industries worldwide, and the three pass oil fired steam boiler addresses this issue effectively. Its design reduces heat loss, lowers fuel consumption, and minimizes emissions. By achieving high efficiency, it contributes to both cost savings and environmental protection.

Additionally, many modern models incorporate features like automatic controls, advanced burners, and heat recovery systems, further enhancing efficiency and reducing operational impact. This combination of performance, durability, and eco-friendliness makes the three pass oil fired steam boiler a forward-looking solution for industries aiming for sustainable growth.

1. Key Selling Points:

Three-pass design for higher thermal efficiency and better fuel utilization.

Stable and high-quality steam output, ideal for food processing, textile, and manufacturing plants.

Customizable solutions in terms of capacity, pressure, and configuration to meet different industry needs.

Automatic control system, easy operation, and reduced labor cost.

High safety standards with multiple protection devices (low water, overpressure, flameout protection).

2. Typical Applications: Food factories, beverage plants, textile mills, manufacturing industries.

1. Key Selling Points:

High-temperature heating under low pressure, ensuring safer operation.

Precise temperature control, suitable for industrial processes requiring stable heating.

Closed-loop circulation system with high efficiency and lower energy consumption.

Flexible fuel options, including natural gas, light oil, and heavy oil.

Low maintenance and long service life with reliable operation.

2. Typical Applications:Paper mills, chemical plants, building materials, printing & dyeing industries.

1. Key Selling Points:

High efficiency and energy saving, with thermal efficiency above 90%, reducing operating costs.

Reliable performance for continuous and stable heat supply in industrial and civil heating systems.

Low-NOx combustion technology, meeting international environmental standards.

Compact structure and easy installation, suitable for new projects and system upgrades.

Durable design, made with high-quality materials for a longer service life and lower maintenance cost.

2. Typical Applications: Industrial heating systems, hospitals, schools, hotels, residential heating.